The new calculation method for Sheet metal repair

What are the differences between the “old” and the “new” calculation methods for Sheet metal repair?

The user was previously limited when it came to describing the damage to the system – only the degree of access (to the rear of the damage) and the damage surface could be specified.

Our time studies have shown that damage is usually repaired from outside, which meant that the old way of describing the damage was outdated. There are now several parameters to describe the damage.

The system now calculates Sheet metal repair times for aluminium as well.

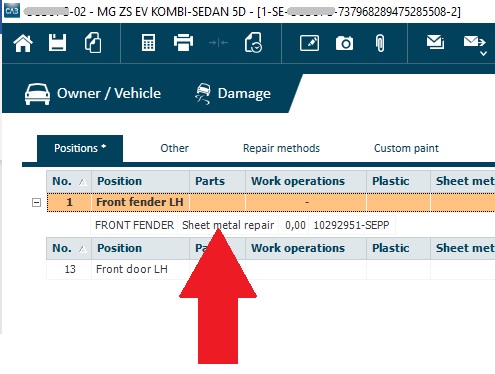

Previously, it was only possible to calculate Sheet metal repair by position, without the system knowing which part it related to. Sheet metal repair is now calculated by spare part. You will recognise this principle from Plastic repairs.

What about existing estimates?

- Existing estimates (created before release 22.9 – before 24.09.2022), containing Sheet metal repair are locked to the ”old” method – even if you should delete all earlier selected Sheet metal repair operations.

- Existing estimates, containing NO Sheet metal repair operations, will use the ”new” method when Sheet metal repair is selected.

- New estimates (created after release 22.9 – 24.09.2022 or later) will use the ”new” method when Sheet metal repair is selected.

How do I get to the new Sheet metal repair dialogue?

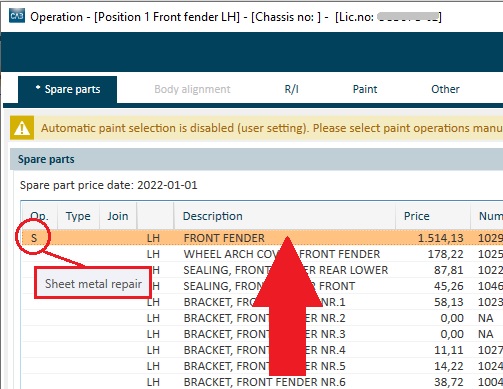

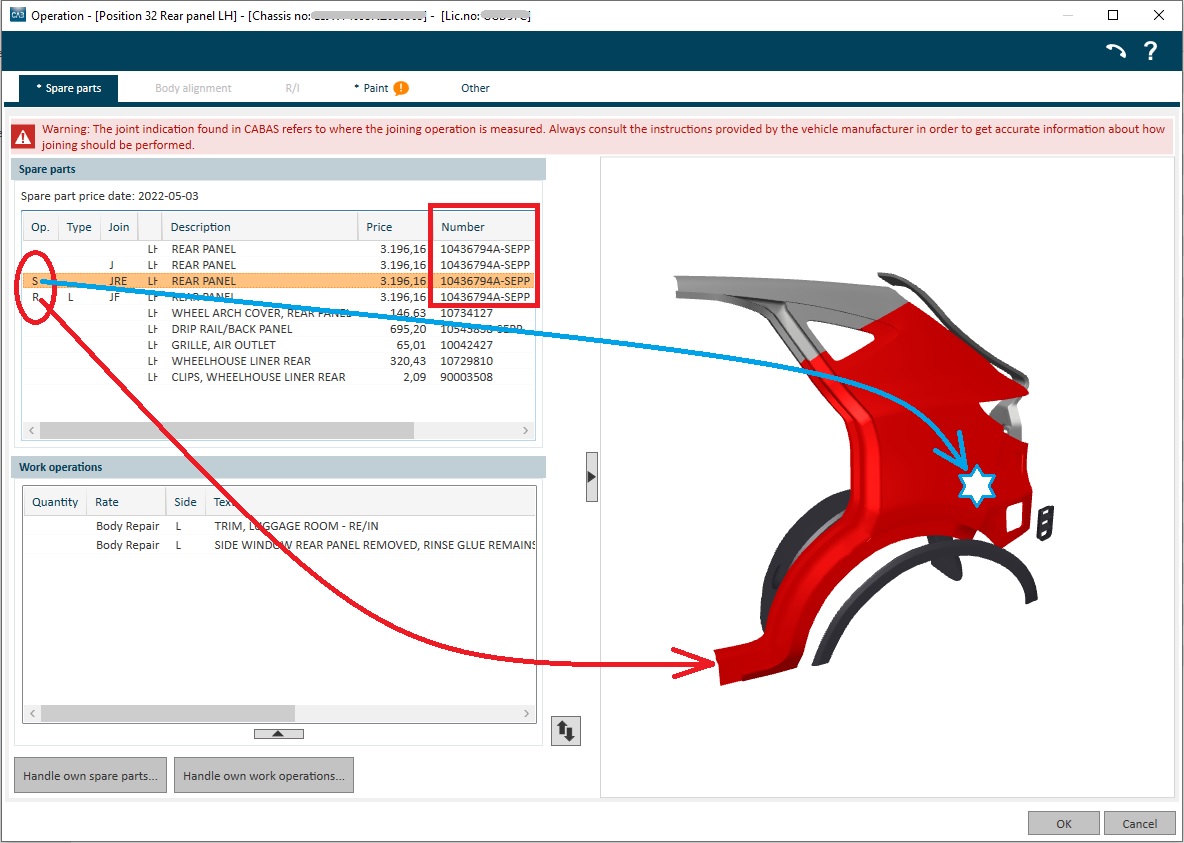

Open a position to add a Sheet metal repair by double-clicking the position name or by selecting the spare part and pressing “S” in the column for the desired position.

With this release, the Sheet metal repair tab will be hidden and will be visible only when handling existing estimates done before release 22.9 – 24.09.2022.

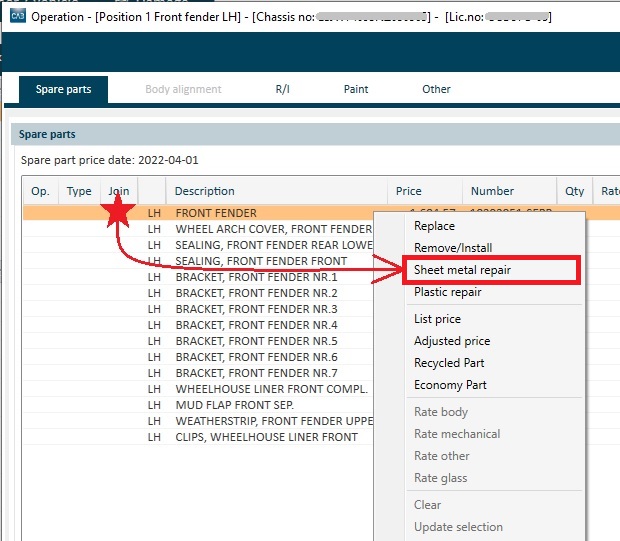

In the opened position, you now select the spare part you want to repair by right-clicking on the spare part text…

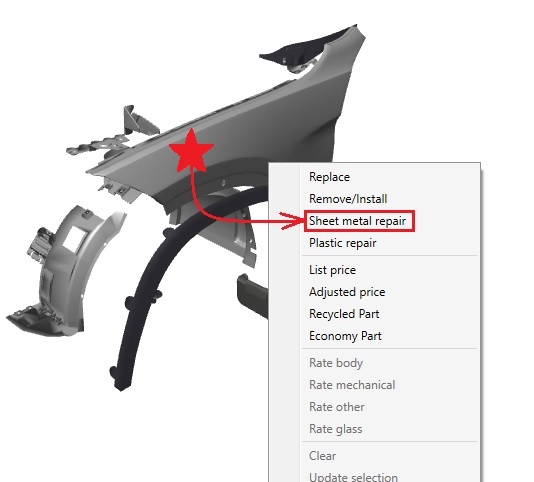

...or by right-clicking on the spare part’s 3D image…

...and selecting “Sheet metal repair”.

How does the new Sheet metal repair dialogue work and what can I do there?

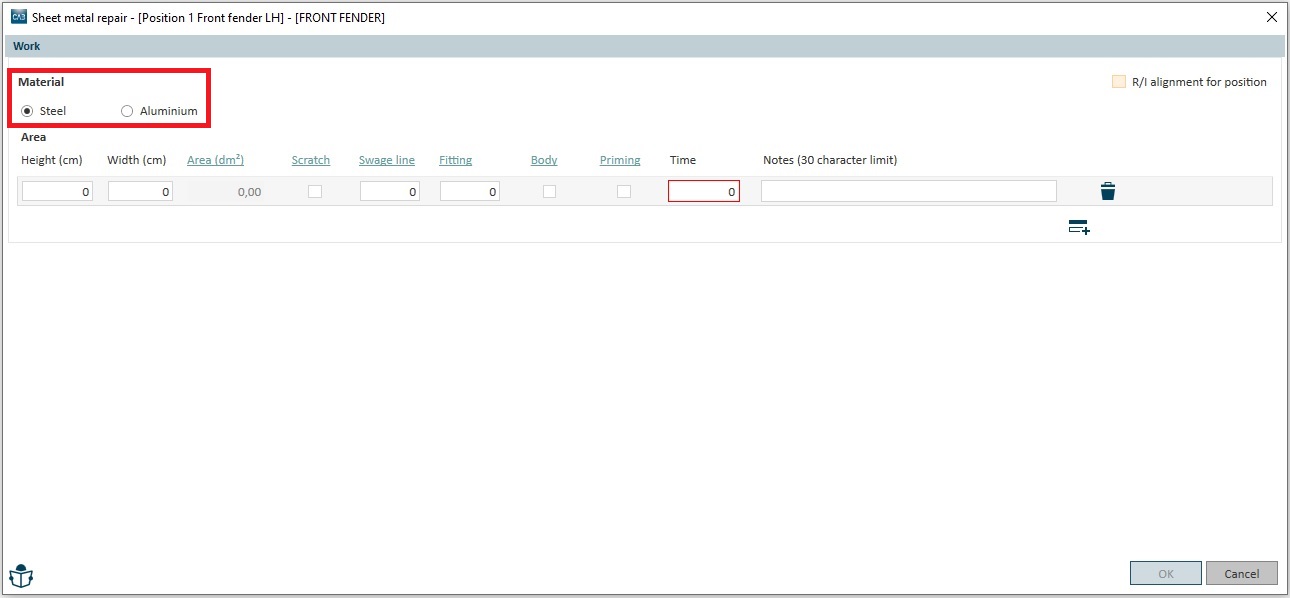

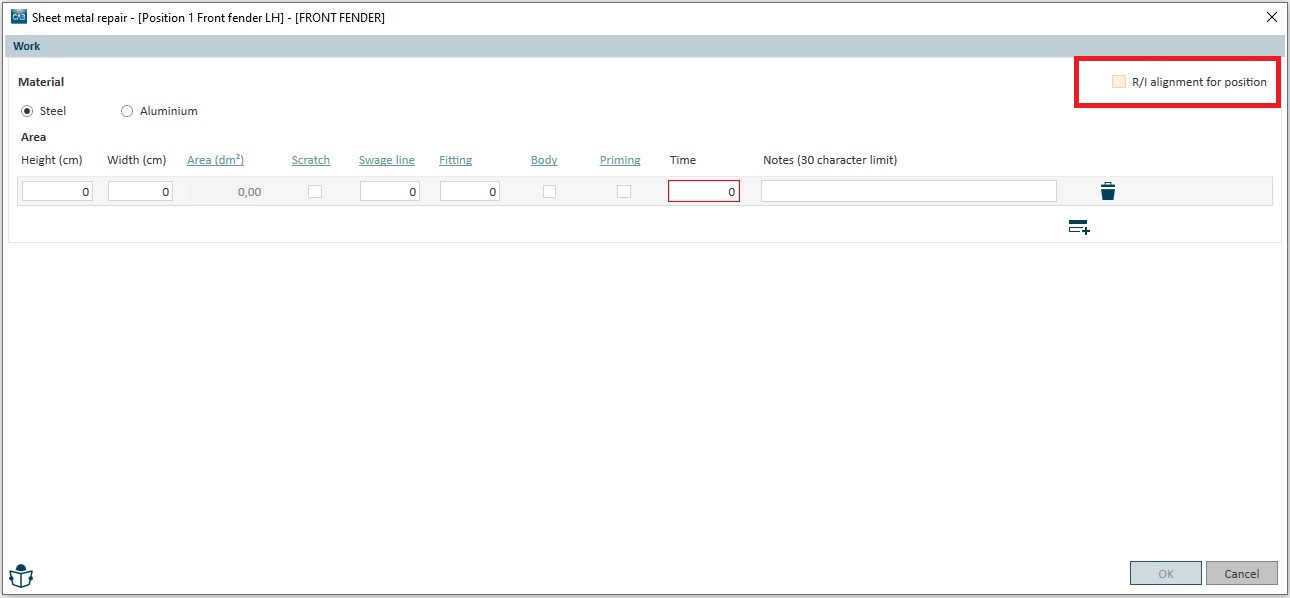

You start by specifying what material the spare part is made of.

Depending on what you enter, the system will calculate different repair times for different materials.

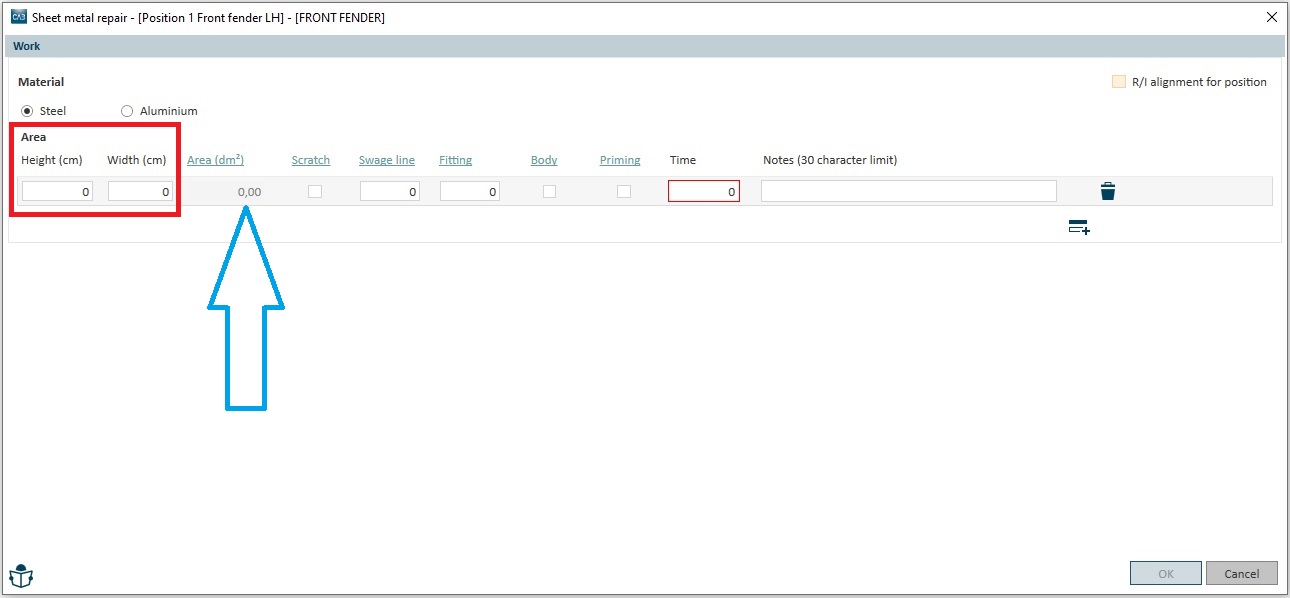

In the next step, the actual damaged surface must be specified (NOT the area you believe will be covered by filler during the repair).

The Hight and Width of the damaged surface must be entered in centimetres. The system will calculate the area directly and present the result in column ”Area (dm2)” (blue arrow above). You cannot enter a damage area manually anymore.

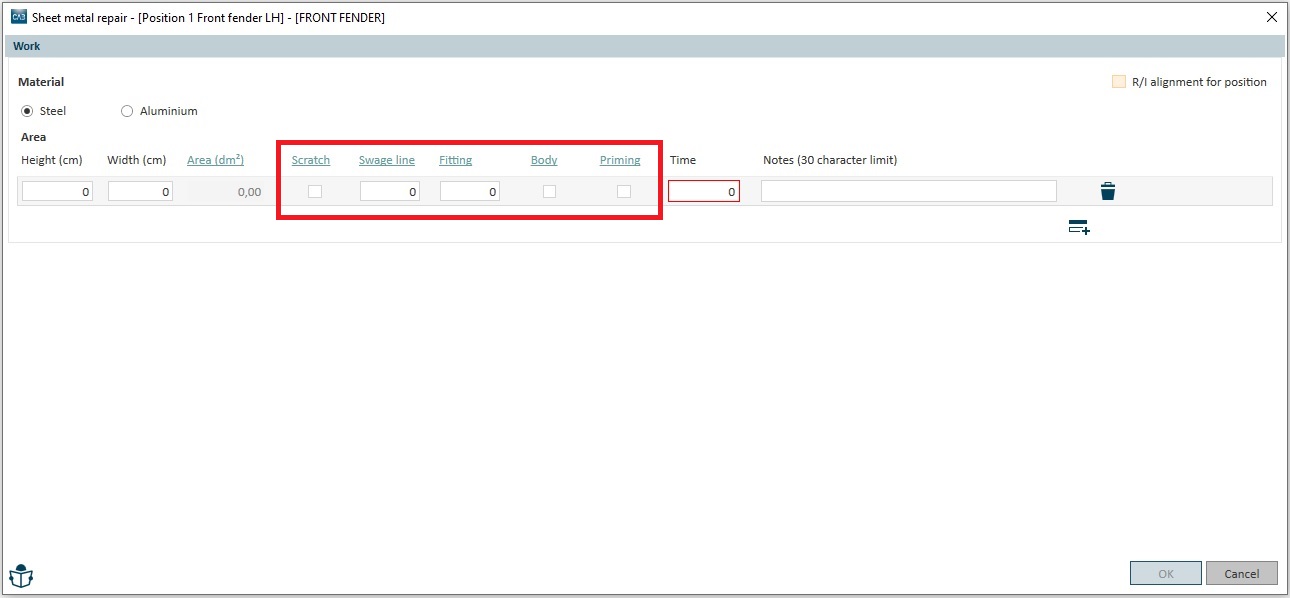

You can now specify additional parameters that can affect the repair time. These parameters are:

- Scratches – is selected, when the damage is repaired solely by grinding and filling, where no surface alignment is required to restore the structure of the surface. Observe, that the panel must be deformed – the time for painting of ”old” surfaces, grinding and filling of scratches is included.

- Swage line – is selected, when a swage line is damaged. Swage lines and folds can be present for design or construction reasons, concave (recessed) or convex (bulging). (max. number = 5)

- Fitting – occurs, when the edge of the spare part is damaged and needs to be adapted to the adjoining part. The damaged area may adjoin several spare parts. The number of spare parts to be fitted to the damage surface must be specified in CABAS (max. number = 3)

- Body – select if the damage surface is covered by underbody sealer

- Priming – select if the car manufacturer requires the panel to be primed before filler is applied

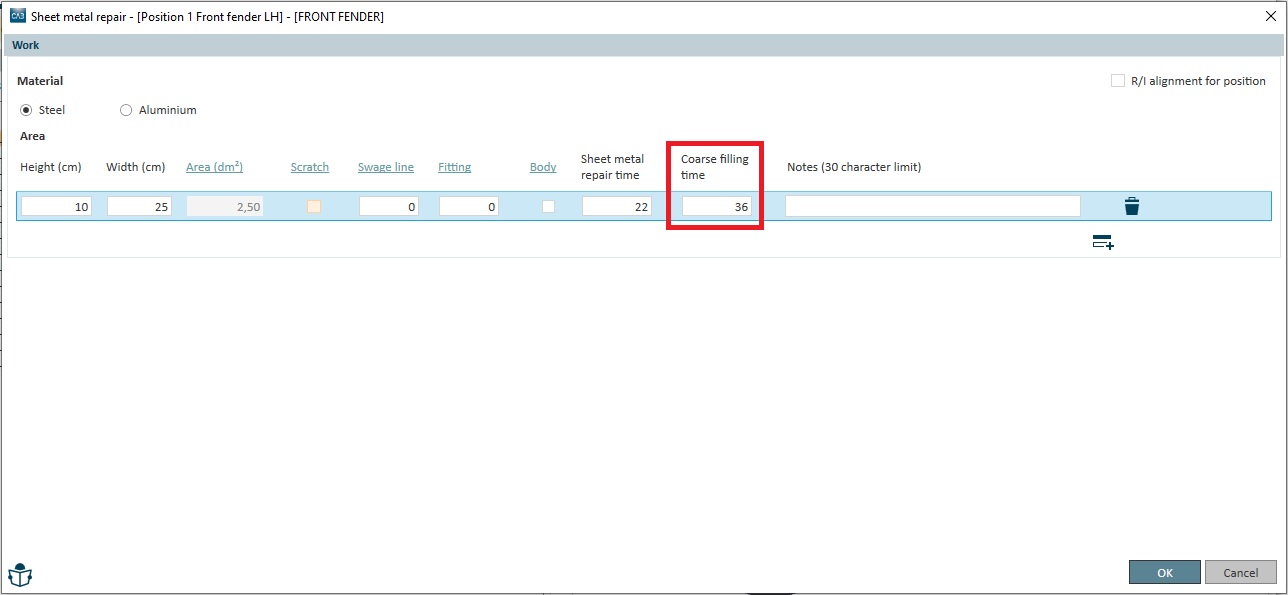

- Coarse filling time – is shown in cases when the operations “Sheet metal repair + Coarse filling” are carried out by different departments (body workshop or paint shop) to assure that the time given for the work will be transferred to the correct workshop department.

OBSERVE! This is to be defined in Settings=>Organisation settings (select what department is applying the coarse filling)*

* - This feature is not available on all markets

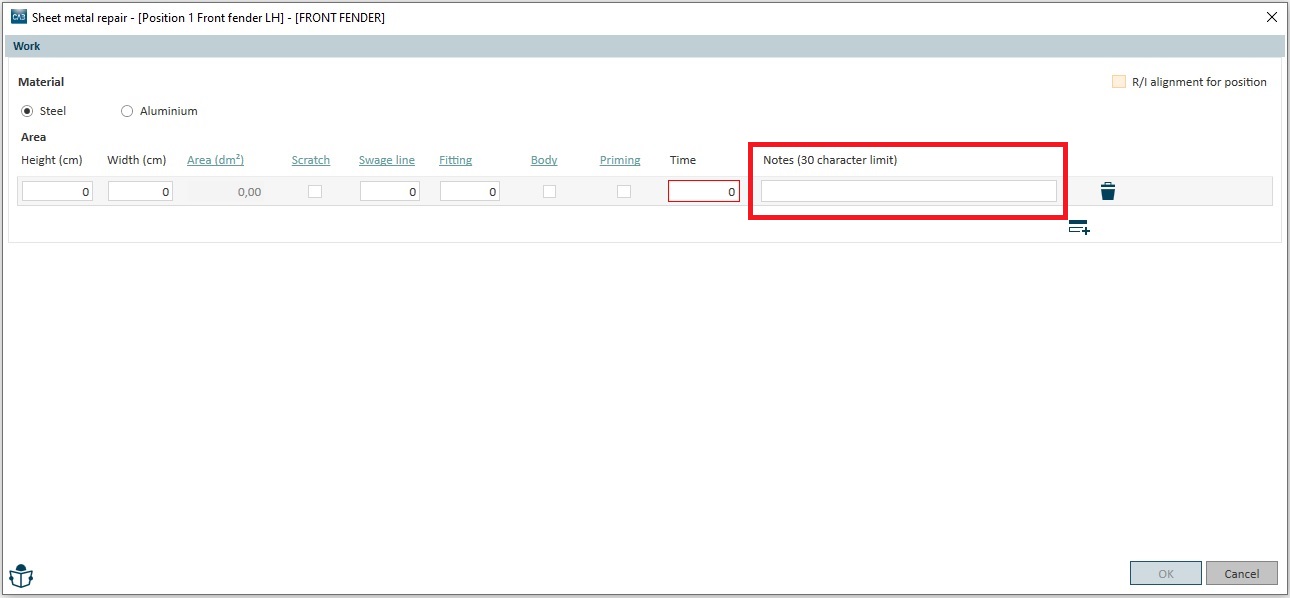

Notes – here you can insert a short explanation – if needed (e.g., where on the spare part the damage is situated or if there are several spare parts with the same name (e.g., “bracket”, you may explain what bracket the repair time is valid for)). Observe: max. 30 characters

Finally, select if the component has to be removed from the vehicle in order to be repaired.

OBSERVE! This operation gives the R/I operation for the main part of the position only!

When you are finished with your damaged area, you may – if necessary – add more new rows. The principle of adding new rows is the same as before: click on the row icon with the plus sign.

If you must delete an existing damage row, just click on the waste bin to the right in the end of the actual damage row.

Can I get help if I have questions about anything in the Sheet metal repair dialogue?

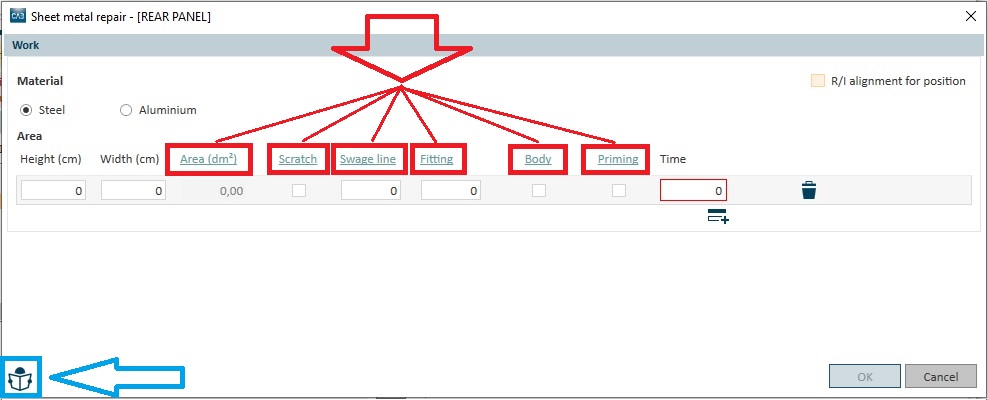

With the new Sheet metal repair in CABAS, we have created new, dynamic user instructions. This means that you can click on a term in the interface (example: red arrows below) and go directly to the correct section in the user instructions.

If you want to read the user instructions in full, you can click on the icon for this as usual (blue arrow below).

How do I get back to the Sheet metal repair dialogue?

If you need to supplement previous selections (changes or additions), go back to the Sheet metal repair dialogue by double-clicking the on “X” in the “Sheet metal repair” column in the Action window and then…

...double-click on the spare part in the Spare Parts window…

…or double-click in the Action window (expanded mode) on the Sheet metal repair row you need to supplement.

More than one operation on the same spare part

It is possible to carry our several operations on one and the same spare part in connection with Sheet metal repair. For the example here below, you can calculate a partial replacement in the front of the rear fender (dog leg) and Sheet metal repair on the remaining part of the rear fender.

Earlier it was not possible to carry out several operations on one and the same spare part number.

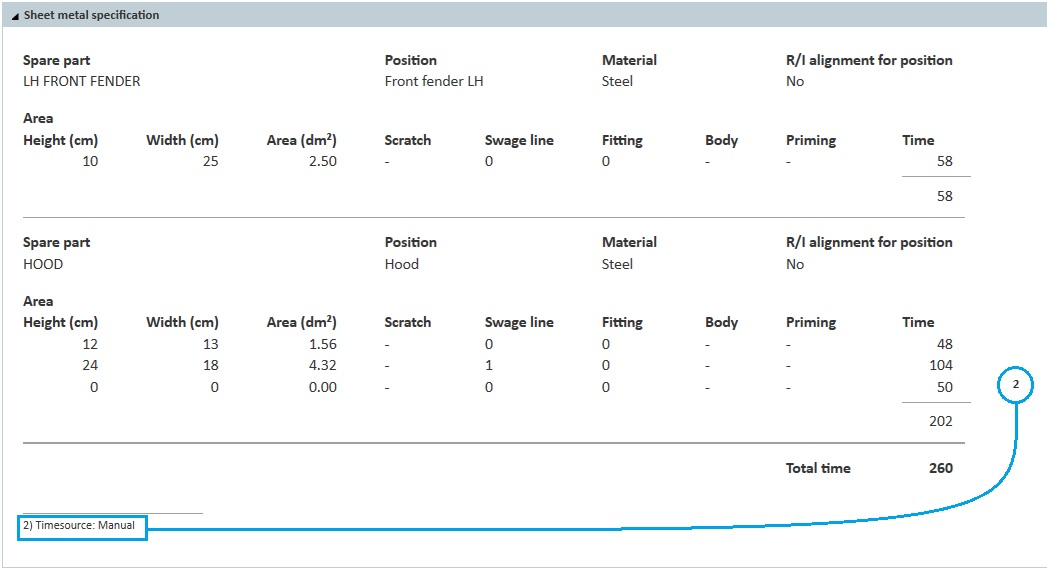

How are the calculated results shown after the implementation of the new way of calculating Sheet metal repair?

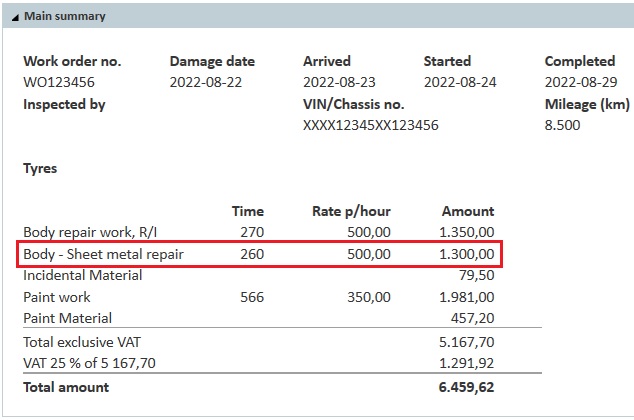

Existing specifications that are affected by the new Sheet metal repair are Main summary and Labour specification.

The Main summary shows Sheet metal repair operations as before with time, hourly rate and cost:

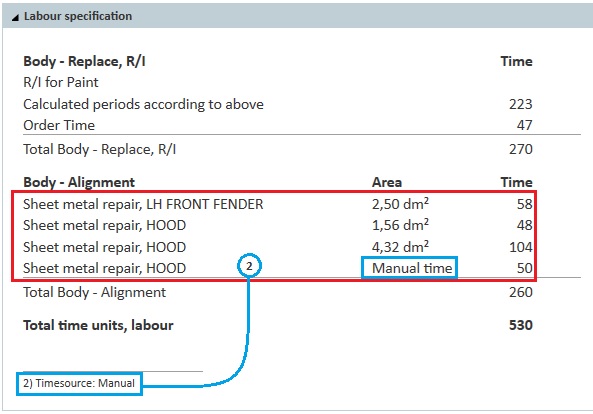

The Labour specification has been given a new look. Now, each damage area is reported with its size and time (degree of accessibility no longer exists). Any time entered manually is marked with footnote 2 (Timesource: Manual):

The system now provides a special specification for Sheet metal Repair (Sheet metal specification). It shows all selections and entries made per damage area and Position per spare part. Information regarding removal of the position’s main part is also provided per spare part. The times are reported per damage area and summed per spare part. Any time entered manually is marked with footnote 2 (Timesource: Manual):